A magnetic drawer filter, often simply referred to as a magnetic drawer, is an industrial device engineered to capture and remove ferromagnetic impurities from free-flowing materials. These filters are particularly effective in separating ferrous metals, such as iron particles, from raw materials in powder processing applications. Unlike traditional sieves or screens, magnetic drawers utilize powerful rare earth magnets to attract and hold contaminants, preventing them from contaminating end products.

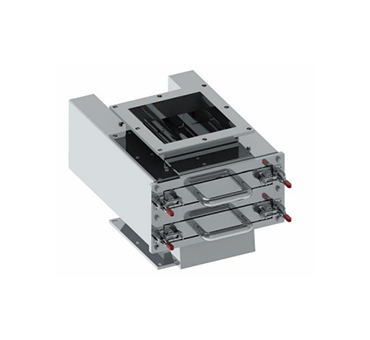

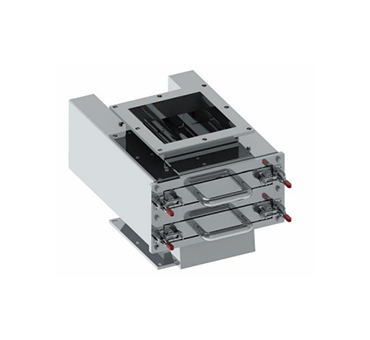

At its core, the magnetic drawer consists of a stainless steel housing that encases multiple layers of magnetic bars. Materials pass through these bars, where the strong magnetic fields—up to 12,000 Gauss—pull out even the smallest ferrous fines, down to 5 microns. This design is ideal for both low-flow setups and high-volume operations capable of handling up to 50 tons per hour. Souwest Magnetech's models, for instance, feature customizable configurations with one, two, or more layers for multi-stage filtration, ensuring thorough purification without disrupting workflow.

One common misconception is confusing magnetic drawers with other drawer-related magnetic products, like magnetic catches for drawers or magnetic locks for hidden drawers. While those are typically used in furniture or cabinetry for securing compartments, magnetic drawer filters are strictly industrial tools focused on material separation. This distinction is important for businesses searching for contamination control solutions rather than hardware accessories.

Key Features of Souwest Magnetech Magnetic Drawers

Souwest Magnetech prioritizes quality and innovation in our magnetic drawer designs. The external frame is constructed from durable 304 or 316 stainless steel, with 316L options available for corrosive environments like chemical processing. Inside, rare earth permanent magnets with N38H-N52 grade neodymium cores provide exceptional strength and longevity.

The magnetic circuit is a standout feature, with well-distributed fields that maximize capture efficiency. Advanced alternating polarity arrays create 360-degree zones, boosting ferrous retention by 35% even in high-velocity flows. For cleaning, our easy-clean versions include a patented quick-release latch that cuts maintenance time by 60%. Ergonomic nylon handles, rated for over 500,000 cycles, and food-grade silicone gaskets make the process user-friendly and hygienic.

Temperature stability is another highlight—our filters remain effective up to 150°C (302°F) thanks to temperature-compensated magnets. Additionally, IP69K-rated housings withstand rigorous washdown procedures, making them suitable for demanding settings. New enhancements like magnetic flux monitoring ports allow real-time verification of field strength without disassembly, while FDA and EU1935 compliance ensures they're safe for food contact.

For those needing automated options, our self-cleaning magnetic drawer filters incorporate a PEEK polymer scraperboard for contact-free cleaning. This design operates reliably from -40°C to 120°C and comes in strengths of 8,000 Gauss for standard food processing, 10,000 Gauss for heavy-duty recovery, and 12,000 Gauss for pharmaceutical purification.

Benefits for Your Operations

Investing in a magnetic drawer filter from Souwest Magnetech delivers tangible advantages that go beyond basic contamination removal. First, it extends equipment life by preventing metal particles from damaging machinery, such as extruders or mills. This translates to reduced downtime and lower maintenance costs, backed by our 5-year performance warranty.

In high-volume environments, the ability to handle large throughputs without flow interruption is invaluable. Operators can simply pull handles to remove the drawer, wipe off accumulated metal, and resume production seamlessly. For industries like plastics or food, this means prolonged cartridge life and fewer replacements, ultimately cutting operational expenses.

Safety and compliance are also enhanced. Features like visual contamination indicators and rapid-change kits for ATEX-rated conversions ensure adherence to stringent regulations. In plastic extrusion lines, for example, these filters effectively remove powdered colorants and resins, maintaining product integrity. Pairing with tools like our Magnetic Trap Efficiency Calculator helps tailor the Gauss rating to your specific material density and flow rate, optimizing performance.

Environmentally, magnetic drawers support sustainable practices by enabling material recycling and reducing waste. Their robust construction, including high-torque nylon knobs tested under ISO 9001 standards, ensures long-term reliability in harsh conditions.

Self-Cleaning Magnetic Drawer Options

For operations requiring minimal manual intervention, Souwest Magnetech offers self-cleaning magnetic drawer models like the MD20×20SF-IG and MD25×25SF-IG. These feature compact dimensions—such as 208mm x 205mm for the MD20—and bar quantities of 2+3 or 3+4, making them versatile for various setups.

Larger models, including the MD150RF-IG and MD200RF-IG, provide greater capacity with heights up to 444mm and diameters of 150mm or 200mm. Line drawings available on our site illustrate these configurations, helping users visualize integration into existing systems. The scraper design eliminates metal-to-metal contact, preserving magnet integrity and simplifying sanitation protocols.

These self-cleaning variants are particularly beneficial in pharmaceutical or food industries, where frequent cleaning is mandatory but time is limited. By automating the removal of ferrous buildup, they maintain consistent efficiency and hygiene.

Applications Across Industries

Magnetic drawer filters find applications in a wide array of sectors. In the food industry, they're essential for flour milling and powder blending, safeguarding against metal contamination that could lead to recalls. Chemical and pharmaceutical operations benefit from their precision in purifying granules and ensuring compliance with purity standards.

Mining and metallurgy use them to extract impurities from ores and powders, while plastics and rubber industries rely on them for clean extrusion processes. Electronics, pigments, dyes, and environmental protection sectors also leverage their capabilities for fine particle separation. Souwest Magnetech's versatile designs make them adaptable to ceramics, electric power, and more, addressing unique challenges in each field.

Choosing the Right Magnetic Drawer for Your Needs

Selecting the appropriate magnetic drawer involves considering factors like material type, flow rate, and required magnetic strength. For standard applications, an 8,000 Gauss model suffices, but pharmaceutical needs may demand 12,000 Gauss. Assess your environment—corrosive settings call for 316L steel, while high-heat operations need temperature-compensated options.

Consulting with experts can streamline this process. At Souwest Magnetech, we provide customization to match your specifications, including multi-layer setups for enhanced filtration. Use our online resources, such as model line drawings and efficiency calculators, to make informed decisions.

Why Choose Souwest Magnetech?

As a leading provider of magnetic solutions, Souwest Magnetech combines decades of expertise with innovative engineering. Our magnetic drawers are built to last, offering superior performance and value. With full documentation for compliance and rapid support, we ensure your investment pays off.

Ready to enhance your contamination control? Explore our range at https://www.magnetsw.com/ and request a free quote today. Contact us at 0574-86666833 or via our website for personalized advice.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية