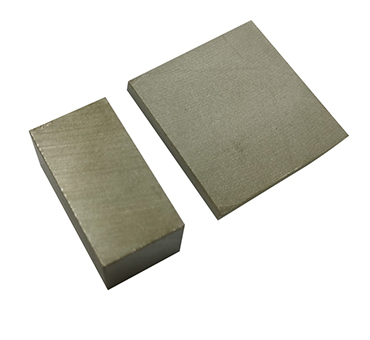

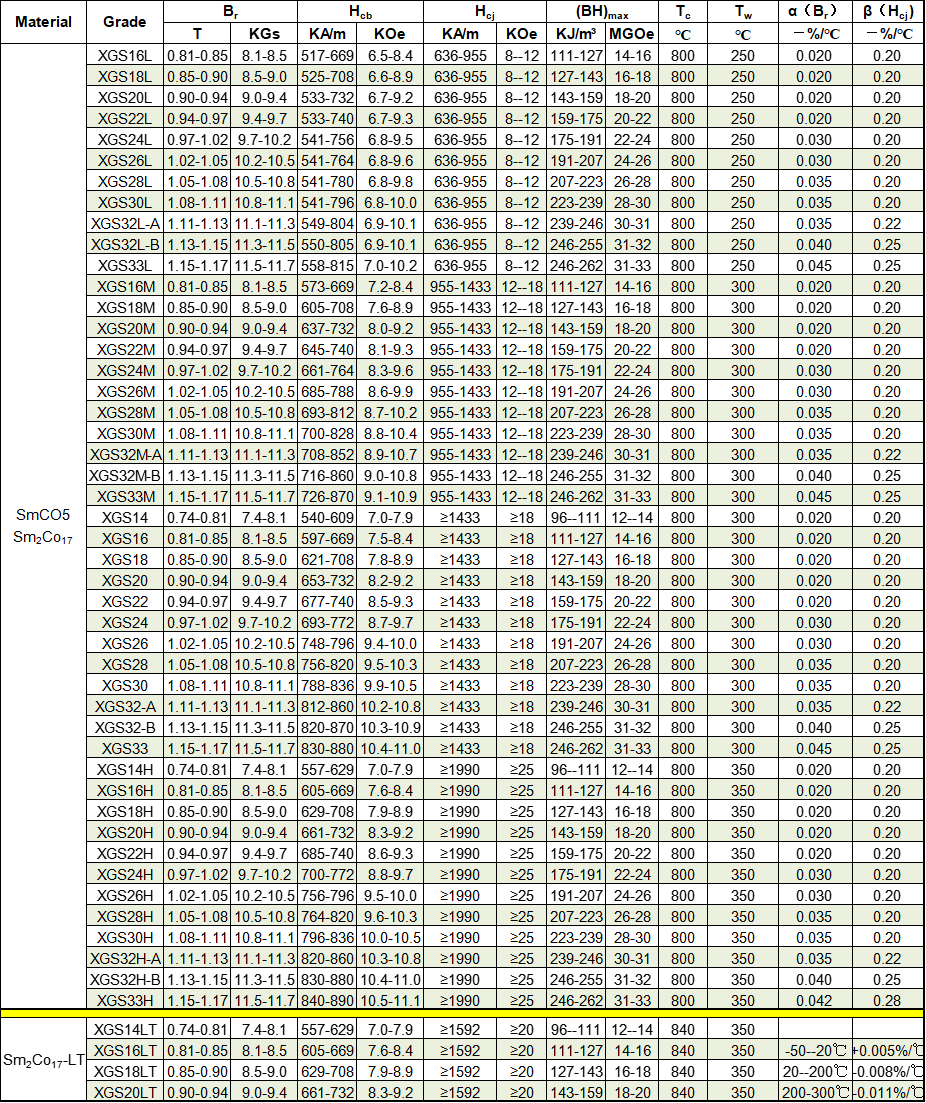

Magnetic Performance Table of Souwest Magnetech Sintered Samarium Cobalt Magnet

What Are Samarium Cobalt Magnets China Used For?

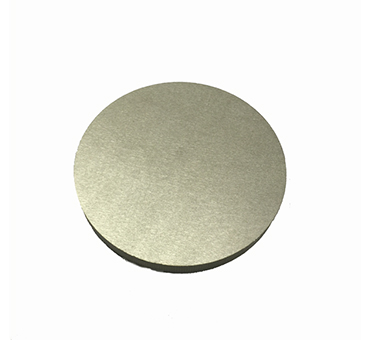

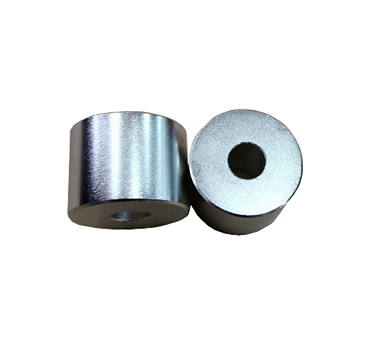

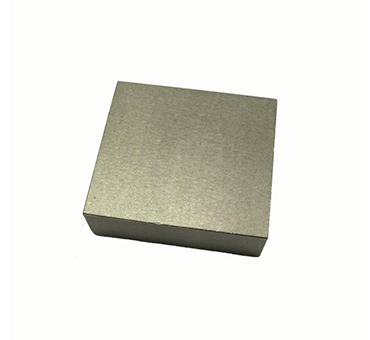

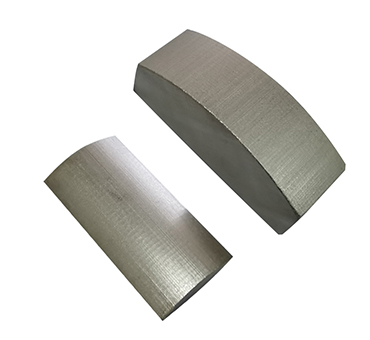

At Souwest Magnetech, we are a leading samarium cobalt magnets supplier, offering high-quality magnets for a variety of applications. Samarium cobalt magnets, also known as SmCo magnets, are renowned for their high-temperature resistance and durability.

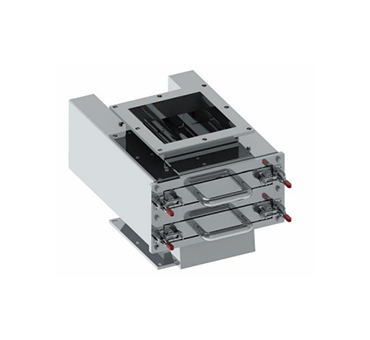

High-Temperature Applications

Samarium cobalt magnets are most commonly used in applications that require high operating temperatures. These include generators and pump couplings, where the magnets’ ability to maintain their magnetic properties at high temperatures is crucial.

Sensors and Motors

SmCo magnets are also widely used in sensors and motors. SmCo magnets' high magnetic strength and resistance to demagnetization make them ideal for these applications, contributing to the overall performance and efficiency of these devices.

Marine Applications

In the marine industry, samarium cobalt magnets are used in various applications due to their resistance to corrosion. This makes samarium cobalt rare earth magnets suitable for use in harsh marine environments.

Automotive, Aerospace, and Military Industries

Samarium cobalt magnets are also used in the automotive, aerospace, and military industries. Samarium cobalt magnets' high-temperature resistance and durability make them suitable for use in these demanding environments.

Food and Manufacturing Industries

In the food and manufacturing industries, SmCo magnets are used for their ability to withstand high temperatures and corrosive environments. This makes them ideal for use in food processing and manufacturing equipment.

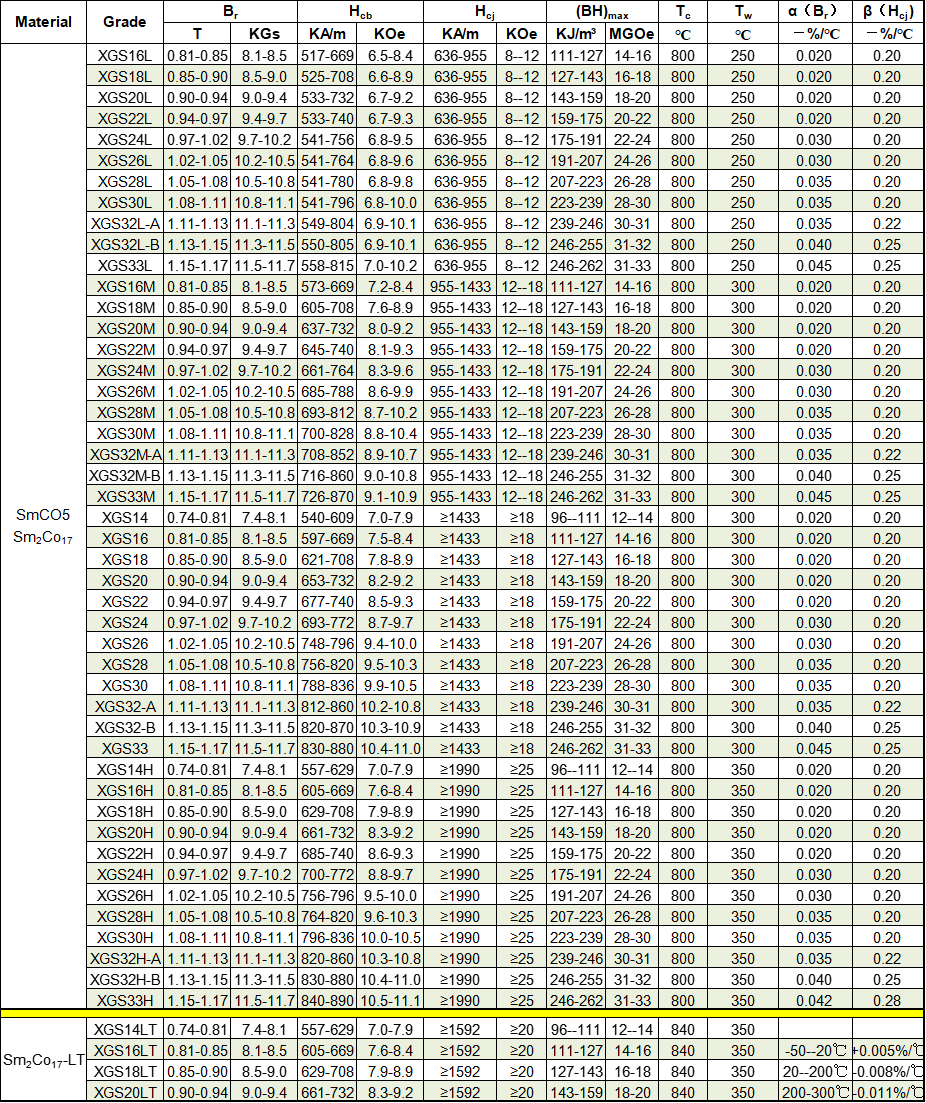

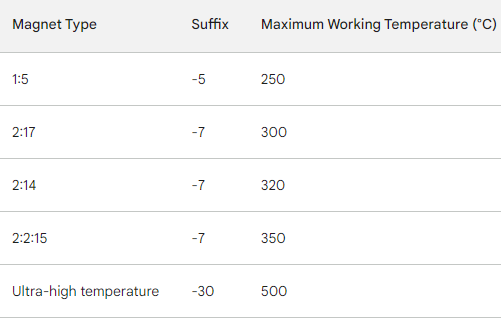

Souwest Magnetech Samarium Cobalt Magnet Temperature Limit

Samarium cobalt magnets are a type of rare earth magnet known for their high magnetic strength and temperature stability. The wholesale smco magnets can withstand temperatures up to 350°C (662°F), making them suitable for a variety of applications in harsh environments. Explores the temperature limit of samarium cobalt magnets and samarium cobalt rare earth magnets' diverse applications in industries like aerospace, automotive, and medical devices.

Souwest Magnetech Other Magnets That Interest You

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية