In the chemical industry's production process, where a large amount of chemical materials is consumed, the presence of metal contaminants poses significant challenges. These contaminants can affect product quality, damage processing equipment, and lead to costly downtime. Moreover, by-products generated during chemical production often contain a large amount of valuable materials, and their recovery is a key process for improving operational efficiency, ensuring environmental compliance, and maximizing economic returns for enterprises. Magnetic drawer filters, as an efficient separation technology, show great potential for application in the recovery of by-products in the chemical industry. This article will explore the optimized application of magnetic drawer filters in the recovery of chemical industry by-products and analyze their technical advantages and economic benefits.

Overview of Magnetic Drawer Filter Technology

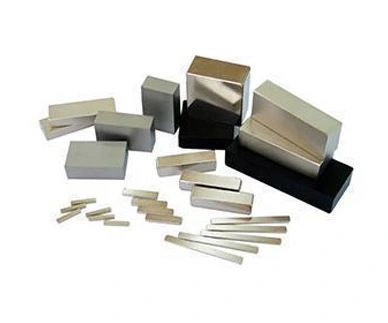

Magnetic drawer filters are devices that use the principle of magnetism for the separation of solids and liquids. By arranging magnetic materials inside the filter, ferromagnetic particles are adsorbed, achieving the separation of clean liquid from solid impurities.

Application of Magnetic Drawer Filters in the Chemical Industry

Improving Product Purity: Maintaining high product purity is crucial in chemical manufacturing. Iron contaminants can alter the chemical composition of the final product, leading to batches being rejected and potential regulatory issues. Magnetic drawer filter ensures the effective removal of these impurities, protecting product integrity.

Equipment Protection: Iron contaminants can cause severe wear to processing equipment, increasing maintenance costs and downtime. By removing these particles, magnetic drawer filters help extend the lifespan of machines and reduce maintenance expenses.

Resource Recovery: Many by-products in the chemical industry contain valuable recyclable iron materials. By partnering with a reliable magnetic materials supplier to utilize high-gradient magnetic bars, companies can ensure magnetic drawer filters efficiently separate and collect these materials. This strategic approach not only aids in resource recovery and cost savings but also enhances the overall sustainability of chemical production lines.

Technical Advantages Analysis

Improved Recovery Efficiency: Magnetic drawer filters can quickly adsorb and separate magnetic particles from by-products, significantly enhancing recovery efficiency.

Ease of Maintenance and Cleaning: The design of magnetic drawer filters allows for quick replacement and cleaning, reducing maintenance costs and labor intensity.

Environmentally Friendly: Magnetic drawer filters reduce the use of chemical cleaning agents, decreasing environmental impacts and the potential for secondary pollution.

Reduced Production Costs: By recovering valuable materials from by-products, enterprises can reduce raw material procurement costs.

Magnetic drawer filters have significant technical advantages and economic benefits in the recovery of by-products in the chemical industry. By effectively removing iron contaminants, these filters can improve product purity, protect equipment, promote resource recovery, and support environmental compliance. With continuous technological innovation and optimization, magnetic drawer filters are expected to become an essential tool for by-product recovery in the chemical industry, driving the industry's green development and the realization of a circular economy.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية