Magnets are essential in modern industries, powering everything from industrial machinery to consumer electronics. At Souwest Magnetech, a leading permanent magnet supplier, we provide both permanent magnets and electromagnets tailored to diverse applications. While both types generate magnetic fields and attract ferrous materials, their characteristics and uses differ significantly. This guide explores the key distinctions between permanent magnets and electromagnets, highlighting the advantages of each and how Souwest Magnetech’s permanent magnetic materials and electromagnetic solutions meet industry needs.

Understanding Permanent Magnets

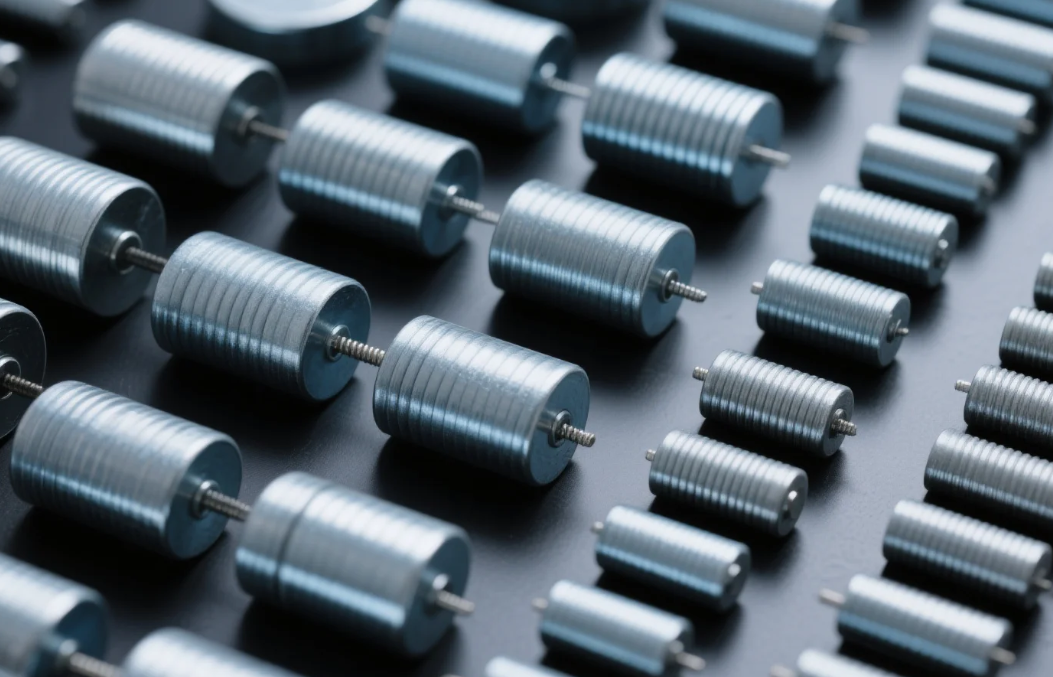

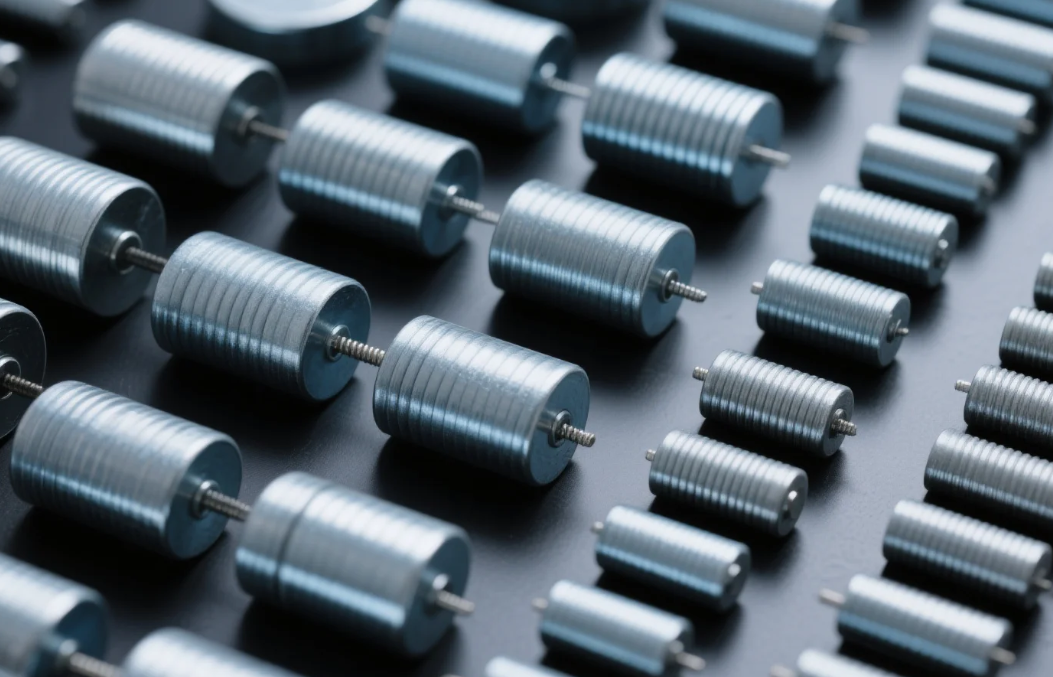

Permanent magnets maintain their magnetic field without requiring an external power source. Composed of permanent magnetic materials like NdFeB (neodymium), SmCo (samarium cobalt), AlNiCo (aluminum-nickel-cobalt), and Ferrite, these magnets are known for their durability and consistent performance. At Souwest Magnetech, our permanent magnets are manufactured using advanced techniques like powder metallurgy and sintering, ensuring high magnetic strength and stability.

Unlike electromagnets, permanent magnets do not rely on electricity, making them ideal for applications where power availability is limited or continuous magnetism is required. Their internal magnetic domains are aligned during production to create a stable magnetic field that resists demagnetization under normal conditions.

Applications of Permanent Magnets

The application of permanent magnets spans multiple industries due to their reliability and compact size. Souwest Magnetech offers a range of permanent magnets, including alnico permanent magnets and NdFeB magnets, for uses such as:

Motors and Generators: Our NdFeB magnets power high-efficiency electric motors in automotive and renewable energy applications.

Sensors and Electronics: Ferrite magnets are used in speakers, headphones, and computer hard drives for their cost-effectiveness and performance.

Magnetic Separators: Our permanent magnet use in magnetic separators ensures efficient removal of ferrous contaminants in food processing and recycling.

Holding and Lifting: Permanent magnet lifters from Souwest Magnetech provide safe and reliable lifting of heavy ferrous objects in manufacturing and construction.

Our permanent magnet supplier services ensure competitive permanent magnet prices and customized solutions, making Souwest Magnetech a trusted choice for industries worldwide.

Understanding Electromagnets

Electromagnets generate magnetic fields only when an electric current flows through a coil, typically wrapped around a ferromagnetic core like iron. This core enhances the magnetic field strength, making electromagnets highly versatile. At Souwest Magnetech, our electromagnetic separators and lifting magnets leverage this technology for applications requiring adjustable magnetic strength and on-off control.

The ability to control the magnetic field by varying the current or reversing its direction sets electromagnets apart from permanent magnets. When the current is turned off, the magnetic field dissipates, allowing for precise control in dynamic applications.

Types of Electromagnets

Souwest Magnetech offers two primary types of electromagnets:

Energise-to-Hold Electromagnets

These electromagnets clamp onto ferrous surfaces only when an electric current is applied. Once the current is turned off, the magnetic field ceases, releasing the object. Our energise-to-hold electromagnets feature a high-permeability iron core and wound copper coil, delivering clamping forces up to 3600N (application-dependent). Available with 12V DC, 24V DC, or 240V AC supply voltages, they have an IP54 rating (IP20 for two-pole connector versions) and a 100% duty cycle. These are ideal for applications like electronic locks and machine guards.

Energise-to-Release Electromagnets (Electro-Permanent Magnets)

Our energise-to-release electromagnets combine a permanent magnet with an electromagnet, clamping to ferrous surfaces without power and releasing only when current is applied. With clamping forces ranging from 230N to 550N and a duty cycle of S2, these magnets are energy-efficient and secure, making them popular for safety-critical applications like fire doors and robotic systems. They operate on 24V DC or 240V AC and have an IP54 rating.

Armature Plates for Electromagnets

To optimize clamping performance, Souwest Magnetech provides armature plates made of high-quality ferromagnetic materials. These plates ensure maximum contact with the electromagnet, minimizing air gaps and achieving optimal pull force. Equipped with rubber washers for flexibility, our armature plates are ideal for clamping to non-ideal surfaces like thin or rusty steel.

Key Differences Between Electromagnets and Permanent Magnets

While both electromagnets and permanent magnets create magnetic fields with north and south poles, their operational characteristics differ significantly:

Power Dependency: Permanent magnets maintain their magnetic field without electricity, while electromagnets require a continuous current to function.

Adjustability: Electromagnets allow for variable magnetic strength by adjusting the current, whereas permanent magnets have a fixed magnetic output.

On-Off Control: Electromagnets can be turned on and off, making them suitable for dynamic applications. Permanent magnets are always “on.”

Strength Potential: Electromagnets can achieve higher magnetic fields than permanent magnets of similar size, depending on the current and core material.

Cost: Electromagnets are often more cost-effective for applications requiring adjustable magnetism, while permanent magnet prices are competitive for static applications.

Energy Efficiency: Permanent magnets are more energy-efficient for continuous use, as they require no power. Energise-to-release electromagnets offer energy savings by clamping without power.

Advantages of Electromagnets

Electromagnets offer several advantages over permanent magnets:

On-Off Functionality: The ability to toggle the magnetic field makes electromagnets ideal for applications like electromagnetic separators and robotic grippers.

Adjustable Strength: Varying the current allows precise control of magnetic force, unlike the fixed strength of permanent magnets.

Pole Reversal: Reversing the current can switch the magnetic poles, enabling versatile applications like magnetic levitation.

Cost-Effectiveness: For applications requiring variable magnetism, electromagnets use fewer materials, reducing costs compared to high-strength permanent magnets.

High Clamping Forces: Souwest Magnetech’s electromagnets deliver powerful clamping forces, ideal for lifting heavy ferrous objects.

Advantages of Permanent Magnets

Permanent magnets also have unique benefits:

No Power Required: Permanent magnet use eliminates the need for electrical infrastructure, making them suitable for remote or power-limited environments.

Reliability: Permanent magnets maintain consistent magnetism without risk of power failure, ideal for permanent magnet lifters.

Compact Design: NdFeB and SmCo magnets from Souwest Magnetech offer high strength in small sizes, perfect for electronics and sensors.

Longevity: With proper storage, permanent magnets retain their magnetism indefinitely, unlike electromagnets that rely on continuous power.

Applications of Electromagnets and Permanent Magnets

Electromagnet Applications

Souwest Magnetech’s electromagnets are used in:

Magnetic Separators: Our electromagnetic separators remove ferrous contaminants in industries like mining and food processing.

Lifting and Holding: Electromagnets are used in cranes and robotic systems for lifting heavy steel components.

Consumer Electronics: Applications include speakers, doorbells, and electric locks.

Scientific Research: Electromagnets enable high-field experiments in physics and material science.

Permanent Magnet Applications

The application of permanent magnets includes:

Permanent Magnet Lifters: Souwest Magnetech’s permanent magnet lifters safely handle heavy ferrous materials in manufacturing.

Motors and Generators: Alnico permanent magnets and NdFeB magnets power high-efficiency motors in automotive and wind energy applications.

Magnetic Separators: Our permanent magnets ensure reliable contaminant removal in recycling and food industries.

Electronics: Ferrite magnets are used in speakers, sensors, and hard drives for their cost-effectiveness.

Technical Considerations for Electromagnets

When designing electromagnets, Souwest Magnetech considers:

Fill Factor: The efficiency of coil winding affects magnetic performance. Our designs achieve up to 80% fill factor, minimizing air gaps.

Current Density: We select wires with appropriate current ratings to prevent overheating, ensuring safe operation up to 155°C.

Cooling: Proper cooling systems are integrated to manage heat from I²R losses, protecting the coil’s insulation.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية