A composite magnetic material and a magnetic head made from this composite magnetic material formed a combination of a body of a magnetic metal material and a magnetic oxide material joined together in such a manner as to provide improved strength while attaining improved manufacturability and regenerative sensitivity at high frequencies. In accordance with the invention, the two bodies are joined together with a thin magnetic metal film initially formed on the oxide material body by vapor deposition or sputtering. The thin magnetic metal film can be made of the same material as the magnetic metal material body.

1. In a composite magnetic material including a first body (2) made of a magnetic metal material and a second body (1) made of an oxide magnetic material joined together, the improvement comprising a thin magnetic film (3) formed on the said second body, and fastening means for joining said second body, having said thin magnetic film, to said first body, said fastening means being disposed between said film and said first body.

2. The composite magnetic material of claim 1, wherein said first body and said thin magnetic film is made of the same material.

3. The composite magnetic material of claim 1, wherein joined surfaces of said first and second bodies have a mirrorlike smoothness.

4. The composite magnetic material of claim 1, wherein said fastening means comprises solder.

5. The composite magnetic material of claim 1, wherein said first body and said thin magnetic film is made of Sendust and said second body is made of ferrite.

6. The composite magnetic material of claim 1, wherein said first body is made of Sendust, said the thin magnetic film is made of a material selected from the group consisting of Permalloy and Alperm and said second body is made of ferrite.

7. In a composite magnetic material including a first body (2) made of a magnetic metal material and a second body (1) made of an oxide magnetic material joined together, the improvement comprising a thin magnetic film (3) formed on a said second body, and fastening means for joining said second body, having said thin magnetic film, to said first body, said fastening means being disposed between said film and said first body, wherein said thin magnetic film on said second body is formed by one of vapor deposition and sputtering.

8. A magnetic head comprising: a front core having a thin magnetic film thereon, a rear core, and fastening means for joining said front core at the said film to said rear core to form a magnetic circuit, said front core is made of a magnetic metal material and said rear core is made of an oxide magnetic material.

9. The magnetic head of claim 8, wherein said front core and said the thin magnetic film is made of the same material.

10. The magnetic head of claim 8, wherein said fastening means comprises solder.

11. The magnetic head of claim 8, wherein said front core and said the thin magnetic film is made of Sendust and said rear core is made of ferrite.

12. The magnetic head of claim 8, wherein said front core is made of Sendust, said the thin magnetic film is made of a material selected from the group consisting of Permalloy and Alperm and said rear core is made of ferrite.

The present invention relates to a composite magnetic material composed of different types of magnetic materials joined together.

More specifically, the invention relates to a composite magnetic material formed as a laminate of an oxide magnetic material such as polycrystalline ferrite and a magnetic metal material such as monocrystalline Sendust. Further, the invention relates to a magnetic head having a magnetic core constructed of such composite magnetic materials joined together so as to form a magnetic head capable of magnetic recording on high coercive recording media while providing excellent high-frequency characteristics.

With the advance of electronic technology, laminated composite magnetic materials have gained a general currency in various fields of technology and are playing an important role in the field of magnetic heads used in magnetic recording.

Ferrite, which is typical of oxide magnetic material, has been used to construct magnetic cores of magnetic heads for video tape recorders (VTRs) and magnetic disc reading/writing units for use with magnetic tapes and discs, respectively, the latter including flexible (''floppy'') discs. The reason for this is that oxide magnetic materials provide a high magnetic permeability in a high-frequency range (several MHz) and excellent abrasion resistance.

Recently, high coercive force recording media represented by, for instance, metal tapes and vapor-deposited metal tapes, have been developed to meet high-density magnetic recording requirements. This development has been accompanied by the extensive development of magnetic materials for magnetic heads capable of use with such high coercive force recording media.

The magnetic core of the magnetic head is mainly prepared from a magnetic material, and oxide magnetic materials such as ferrite are typically used. However, as the saturation magnetic flux density of the oxide magnetic material is about 5,000 gauss, a magnetic head constructed of such a material is unusable for magnetic storage on a high coercive force recording medium having a coercive force of more than 1,000 oersteds.

Attempts have been made to use for a magnetic head a magnetic core made of a magnetic material such as Sendust having a high saturation magnetic flux density. However, the disadvantage is that, when such a magnetic metal material is used to form a magnetic head, the regenerative sensitivity of the magnetic head is reduced because of eddy-current losses in the high-frequency range.

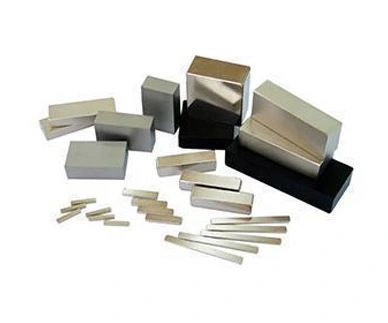

Since a magnetic head having a magnetic core constructed of simple magnetic materials have various disadvantages, there has been proposed a magnetic head using a composite magnetic material, as shown in FIG. 1. In this magnetic head, a laminated composite magnetic material is used for the magnetic core, namely, a magnetic metal core 11 made of Sendust is sandwiched between oxide magnetic cores 12 made of ferrite to compensate for certain magnetic characteristics in the high-frequency range and improve the regenerative sensitivity of the head. The three cores are joined with silver solder.

However, such a composite magnetic material used as a magnetic core has disadvantages including a reduction in strength and difficulties in manufacture as there is required a process for sandwiching the magnetic metal core 11 between the oxide magnetic cores 12 before they are soldered.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية