1. What are NdFeB permanent magnets?

NdFeB magnets, commonly known as neodymium magnets, which are made of neodymium, iron, boron and some other substances through a special process. The strong magnetic force mainly comes from the intermetallic compound Nd2Fe14B. They are also known as rare earth permanent magnets because they contain about 30% of rare earth neodymium.

2. Classification

The bulk neodymium magnets for sale can be mainly divided into three categories: sintered NdFeB magnets, bonded NdFeB magnets, and hot-pressed NdFeB magnets.

Souwest Magnetech offers customized sintered NdFeB magnets, bonded NdFeB magnets

◎Sintered NdFeB Magnets

The powder metallurgy process is used to make blanks by melting, powder making, molding and sintering, and then made into finished products of various shapes and sizes by grinding, cutting and surface treatment. It is the most widely used and accounts for more than 95% of production.

1) Characteristics

※Sintered NdFeB permanent magnets have strong magnetic force.

The main phase of the magnet is the intermetallic compound ND2FE14B, which is said to have a theoretical energy level of 64 MGOES, and is now industrially produced as N55, with an energy level of 53 MGOES or more. The magnetic force of sintered NdFeB magnets is so strong that they can pick up 400 times their weight of pure iron. Compared to magnets of other materials, sintered NdFeB magnets have a very high magnetic power but a very small dimensional mass. Generally speaking, a very small sintered NdFeB magnet can get the effect of a magnet several times larger in size and weight.

※Sintered NdFeB permanent magnets are easy to process.

Sintered NdFeB permanent magnet blanks can be processed into various shapes and sizes of products by grinding, cutting, wire cutting, hollowing, and multi-wire processes. Precise dimensional control can be obtained during the machining process.

※Sintered NdFeB permanent magnets need electroplating.

The Nd-rich phase, which is the secondary phase of sintered NdFeB, is susceptible to oxidation and corrosion, so the magnets need surface protection treatment. According to the different requirements of magnet environment, surface treatments are available such as phosphating, electroplating, chemical plating, electrophoresis, vapor deposition, which plating with zinc, nickel, nickel-copper-nickel, gold, chromium, aluminum, epoxy resin, Parylene, Teflon, etc.

※Sintered NdFeB magnets are available in a wide range of performance grades, with operating temperatures ranging from room temperature to 260 degrees Celsius.

Classified by magnetic energy product, grades from low to high as N25,N28,N30,N33,N35,N38,N40,N42,N45,N48,N50,N52,N54,N55. The higher the magnetic energy product, the stronger the magnet.

In some grades, letters are added to the magnetic energy product, which represents the coercivity level of the magnet, or reflects the high temperature resistance level of the magnet. If there is no letter after the magnetic energy product, then the magnet is standard temperature neodymium, and the working temperature should not exceed 60 degrees Celsius. Here are the specific letters and the working temperature. Sintered NdFeB RH grade can work up to 260 degrees Celsius.

Al. | Max Working Temperature(℃) | Grades |

M | 100 | N35M,N38M,N42M,N45M,N48M,N52M |

H | 120 | N35H,N38H,N42H,N45H,N48H,N50H,N52H |

SH | 150 | N35SH,N38SH,N42SH,N45SH,N48SH,N52SH |

UH | 180 | N35UH,N38UH,N42UH,N45UH,N48UH,N52UH |

EH | 200 | N35EH,N38EH,N42EH,N45EH, |

AH | 220 | N35AH,N38AH,N42AH,N33AH |

TH | 240 | N30TH,N33TH,N35TH,N38TH,N40TH |

RH | 260 | N30RH,N33RH,N35RH,N28RH |

For the performance of each grade, see the link……

2) Applications

Magnetic separators, permanent magnet cranes, various electric motors, generators, high performance motors, magnetic resonance imaging (MRI), sensors, speakers, consumer electronics and green energy are among the many commercial sectors.

◎Bonded NdFeB permanent magnets

The magnetic powder with Nd2FE14B as the main phase is mixed with the adhesive and molded, extruded or injected using complex and precise dies.

1) Advantages

Directly formed into the final size, high dimensional accuracy, large freedom of shape, good mechanical strength, and light specific gravity.

Bonded NdFeB permanent magnets can be made into a variety of thin-walled parts, shaped parts and other products, which can solve the problems of sintered NdFeB -- difficult to precision processing into special shapes, easy to crack, breakage, not easy to assemble in the process, etc.

2) Disadvantages

New products need to open molds, and the magnetic properties are much lower than those of sintered NdFeB.

3) Applications

In computer field: hard disk drive, CD-ROM drive, etc.;

Office automation equipment: scanner motor, printer drive motor, laser printer magnetic roller, etc.;

Automotive micro motor and sensor products: wiper motor, EPS sensor, etc.;

Other kinds of household appliances: digital products and motors, etc.

◎Hot-pressed NdFeB magnets

A radially oriented ring magnet is formed through a unique hot extrusion process, by using fast-hardened nano gold NdFeB magnetic powder. The orientation is not by external magnetic field, but by mechanical extrusion to form a completely dense nanocrystalline structure.

1) Characteristics

The magnetic energy is the same as that of sintered NdFeB, without adding heavy rare earths of dysprosium and terbium. But the denseness and corrosion resistance are better than sintered NdFeB. It also has high heat resistance, and the operating temperature can reach 180℃-200℃.

2) Applications

It can partially replace the common type of sintered NdFeB magnets in the field of EPS, servo motors, power tools and other energy efficient motors.

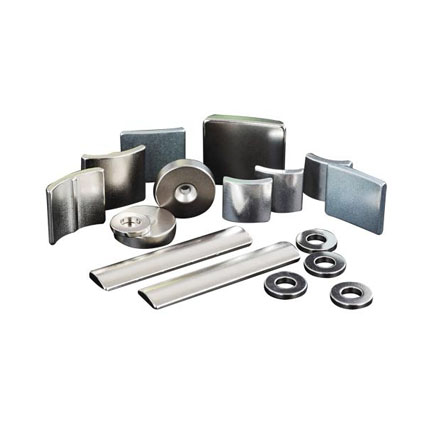

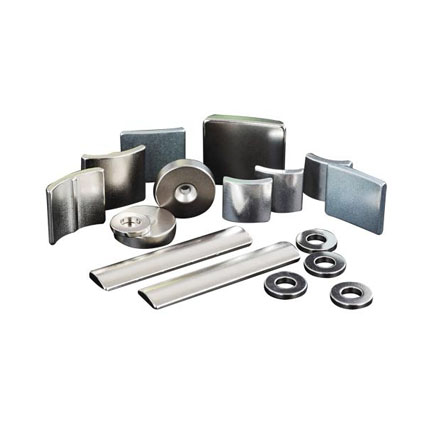

In addition to the above classification, the NdFeB magnets for sale can also be classified according to their shapes, such as cylindrical neodymium magnets, arc segment neodymium magnets, neodymium block magnets, and so on. Have more questions about NdFeB magnets? Contact us for help now!

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية